—Mohammed Noorul Hussain, KU Leuven

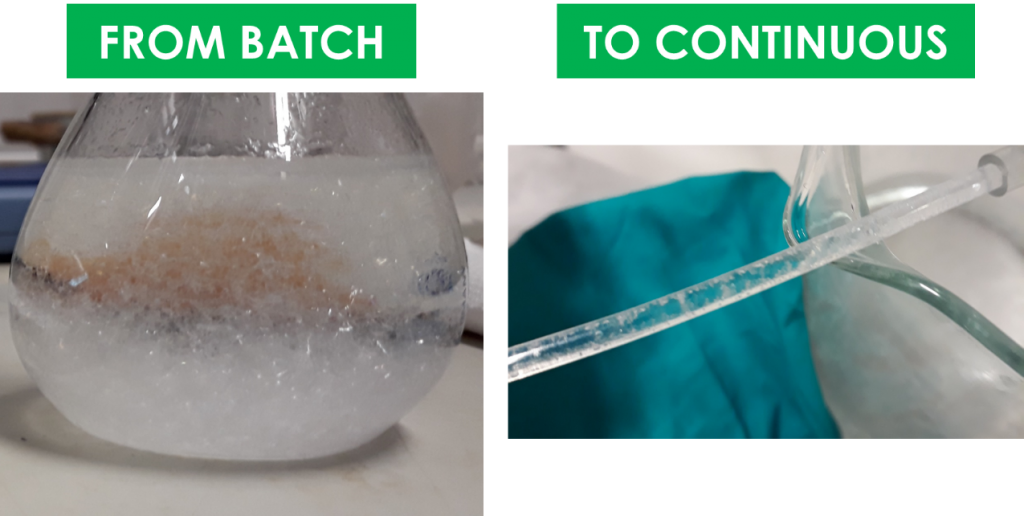

The pharmaceutical industry that is leading a $1000 Billion worldwide market, is looking forward to a new future with the use of techniques like ultrasound. Ultrasound can potentially increase nucleation rates that will reduce the production time. Also, as the industry is fast moving towards continuous crystallization by replacing the existing cumbersome batch reactors, isn’t it important to question if we know what actually goes on behind a continuous sonochemical crystallization process?

No process is based on a single physical phenomena. This applies to the process of pharmaceutical production as well; adding sonochemistry to it makes it quite a challenging topic to understand. In principle, a continuous chemical process is subject to the concepts and theories of mainly chemistry and fluid dynamics, but with the addition of ultrasound the acoustics also become relevant. These are the main engineering aspects that need be understood and to a certain extent explored.

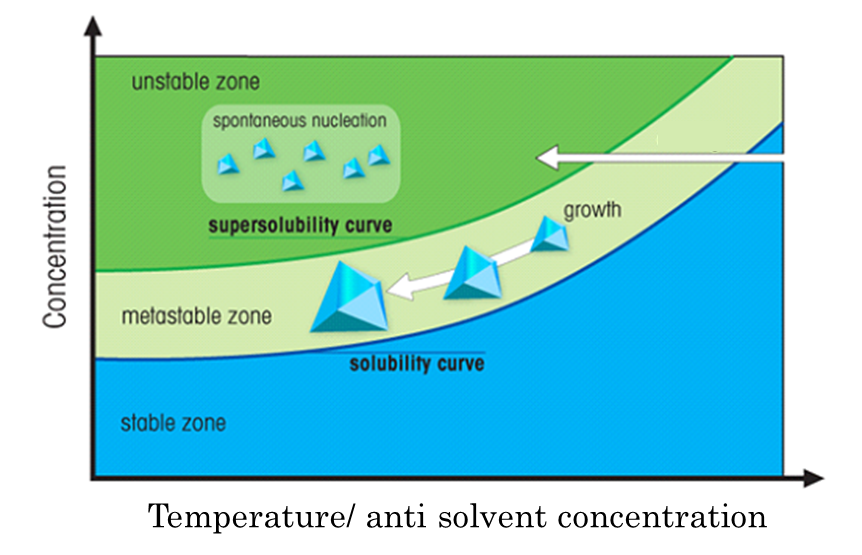

Looking at the chemistry, crystallization is basically formation of crystalline solid phase of solute from a solution. Synthesized crystals of an active pharmaceutical ingredient (API) are dissolved in a solvent and the process of creating a super saturated state to recrystallize the dissolved API inherently constitutes the crystallization process. The existence of a gap between the saturation level and first crystal formation called the Meta-Stable Zone is of primary importance in crystallization techniques. There are mainly two techniques to create super saturation which are namely cooling crystallization and anti-solvent crystallization. In both these techniques the solution is brought to a meta stable zone by either cooling the solution or by adding an anti-solvent.

(Source: http://www.iycr2014.org)

(Source: http://www.iycr2014.org)

Crystallization in flow with the application of ultrasound is where the concepts get interdisciplinary. Ultrasound works through creating cavitation bubbles that in turn help in creating nucleation and reducing the meta stable zone width. While the flow is largely governed by the Navier-Stokes equations, the pressure waves from ultrasound create complicated pressure zones with cavitation that collectively work to optimize the chemical conditions of the system in order to enhance nucleation rates and also to achieve other goals such as polymorph control. The need for interdisciplinary understanding is further enhanced when new reactor designs are needed as per the suitability of each pharmaceutical product from the labyrinth of products that are based on crystallization. The most important acoustic aspect that affects crystallization is the frequency of the ultrasound pressure waves. The frequency of ultrasound that generates cavitation is between 20 kHz to 5 MHz, so any design must comply with this practicality. Also every transducer/horn has its own resonance frequency (the frequency at which the performance is the highest) that is altered at bit depending on the system that it is connected to, therefore this must also be taken into account. The second most important acoustic aspect is the power of the ultrasound that directly affects crystal growth. This is subject to the volume of solution and crystal growth requirements.

With these factors in control the multiple possibilities can be explored in order to develop sophisticated, market-ready continuous sonochemical crystallizers.

- Global Pharmaceutical Industry – Statistics & Facts, statista.com.

- Jeroen Jordens, Tessa Appermont, Bjorn Gielen, Tom Van Gerven, Leen Braeken, Sonofragmentation: Effect of Ultrasound Frequency and Power on Particle Breakage, Crystal Growth & Design,2016, 16, 6167-6177.

- Jeroen Jordens, Bjorn Gielen, Leen Braeken, Tom Van Gerven, Bjorn Gielen, Piet Kusters, Determination of the effect of the ultrasonic frequency on the cooling crystallization of paracetamol, Chemical Engineering and Processing: Process Intensification,2014, 84, 38-44.

- Mohammed Noorul Hussain, Isam Janajreh, Acousto-chemical analysis in multi-transducer sonochemical reactors for biodiesel production, Ultrasonics Sonochemistry, 2018, 40, 184-193.

- Mohammed Noorul Hussain, Isam Janajreh, Numerical Simulation and Experimental Testing of Novel Sonochemical Reactor for Transesterification, Waste and Biomass Valorization, 2017, 1-15.