— Ekim Sarac, University of Göttingen

Sound is a waveform consisting of density variations in a medium (such as gas, liquid or solids) propagating away from the source. The immediate property of sound is its frequency which is mostly measured in cycles per second, or hertz (Hz). Hertz, equal to the reciprocal of second, is the unit of the frequency.

Sound is with us in everywhere throughout the day. Without any dispute, sound has enormous effect on feelings, memories, in short on human psychology. Humans are capable to hear the sound wave with the frequency nearly between 20 Hz and 20 kHz (1 kHz = 103 Hz). And we lose sensitivity to higher frequencies as we age. Frequency of a loudspeaker in a television can operate up to about 10 kHz that is the half of the human capabilities. Sonic describes sounds in nominal frequency range of the human ear. The sound waves having a frequency greater than 20 kHz are classified as ultrasound, whereas the waves having lower frequency than 20 Hz are called as infrasound [1].

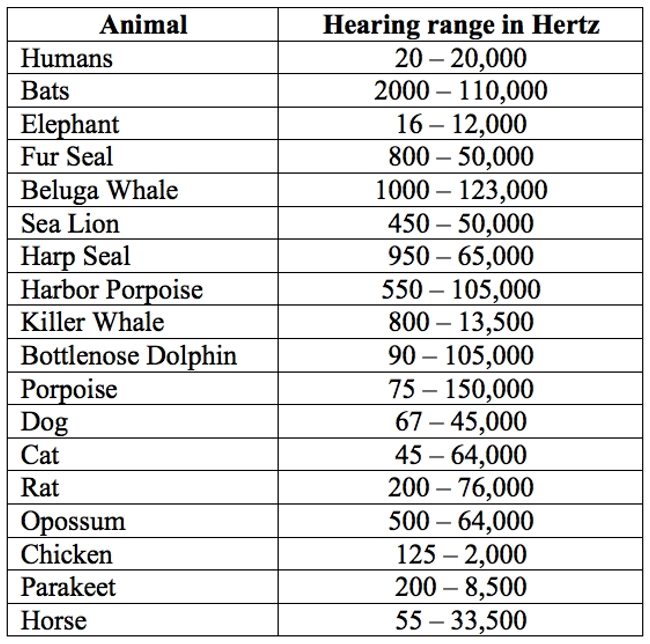

Each animal has different hearing range and these are all different than humans have. Salamander can only hear in the range 50-220 Hz and the common house spider can hear the sound between 20 Hz and 45 kHz. Table 1 represents the hearing ranges of some animals. The bats ear can operate in the frequency range 30-80 kHz, while toothed whales can hear the frequencies up to 200 kHz. The reason of difference is the change in speed of sound in water and air. Speed of sound in water is three times that in air; therefore, higher frequencies are applied in water.

Table 1: Different hearing ranges of some animals

Ultrasound is employed in many science and technology applications. First, as we all know, ultrasound has an applications in medicine. In diagnostic sonography (ultrasonography), ultrasound is used to as diagnostic imaging technique to observe body structures including tendons, muscles, joints, vessels and internal organs for possible pathology or lesions. The ultrasound frequency used for that purpose is in the frequency range of 2 to 18 MHz (106 Hz = 1 MHz), which is hundreds times greater than the upper limit of human hearing range [3].

Second, ultrasound technology offers great potential in industrial applications, such as welding, cutting, punching, thermofixing, washing, embossing, sealing and so on. Also in today’s engineering technology, special ultrasonic machines are being developed and built in order to automate processes and combine working steps [4].

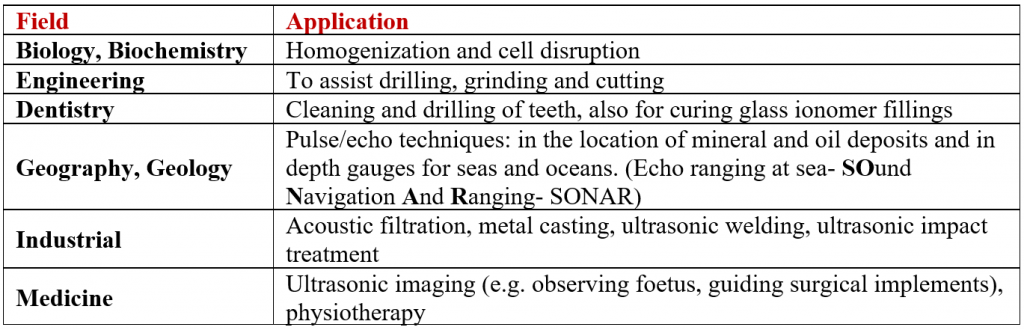

Third, ultrasound have been using in cleaning technology since 1950 [5]. Ultrasonic cleaners offer perfect cleaning of wide range of materials in short time. Different type of solvents (e.g. alcohols, organic compounds) depending on the material can be used, but mostly the water is used as a cleaning solvent. According to the application, temperature becomes another parameter for ultrasonic cleaning. In daily life, ultrasonic cleaners are generally operated in the frequency range of 20 to 50 kHz in order to clean jewelry, lenses, dental and surgical instruments, watches, car fuel injectors, musical instruments and so on. Additionally, apart from the daily usage, industrial metallurgy and semiconductor industry, ultrasonic cleaners are widely used in different operation frequencies. Brief summary of some uses of ultrasound is given in Table 2.

Table 2: Some industrial uses of ultrasound [6]

Finally, ultrasound is employed in processing technology, because of its capability to mix and improve chemical reactions. Sonochemistry describes the chemical effects resulted by subjecting a chemical reaction to the influence of sound waves [6]. As distinct from the other energy sources, ultrasound is not directly linked to interaction with the molecules. Energy of sound activates chemical reactions through acoustic cavitation, such as formation, growth, oscillation and collapse of the bubbles in a liquid. Collapsing of bubbles lead to high temperature (higher than 5000K) and pressure (higher than 1000 atm) spots inside the bubble and initiate the chemical reaction [7].

Employing of ultrasound in milli or microstructure devices provide several advantages over the conventional reaction systems. These microfluidic devices offer improved heat and mass transfer coefficient, due to low characteristic length scale and high surface-to-volume ratio. Additionally, for high parameter reactions, small volumes allow safer handling than the large scale ones.

Therefore, in our project (European Training Network for Continuous Sonication and Microwave Reactors-COSMIC), ultrasound and microwave are used as alternative energy sources for continuous processing which is a flow production method contrasted with batch production technique. Continuous processing offers controlled and intensified process and high yield production in processing applications (e.g. mixing, emulsification, extraction, impregnation, filtration and crystallization) for fine-chemicals and pharmaceuticals industries [8].

- Leighton, T. (1996). “The Acoustic Bubble”. Academic Press, London.

- An interactive eBook on the Physics of Sound. (07 December 2017). Retrieved from: https://soundphysics.ius.edu/?page_id=2657.

- Carovac, L., Smajlovic, F., and Junuzovic, D. (2011). “Application of Ultrasound in Medicine”. Acta Inform Med, vol 19, pp 168-171. doi: 10.5455/aim.2011.19.168-171

- Keilman, G. (2016). “Unusual Applications of Ultrasound in Industry”. Phys Proc, vol 87, pp 79-84.

- Mason, W. P. (1981). “Physical Acoustics Volume XV”. Academic Press, London.

- Mason, T. J., Lorimer, J. P. (2002) “Applied Sonochemistry- The Uses of Power Ultrasound in Chemistry and Processing”. Wiley-VCH Verlag, Wienheim.

- Rivas, D. F., Kuhn, S. (2016). “Synergy of Microfluidics and Ultrasound”. Top Curr Chem (Z), Vol 774 (70). doi: https://doi.org/10.1007/s41061-016-0070-y

- Mason, T. J. (1990) “Advances in Sonochemistry”. JAI PRESS LTD, London.

One comment

Pingback: Weber Ultrasonics – Ultrasonic Partner Company – European Training Network for Continuous Sonication and Microwave Reactors